WHAT WE DO?

KARNATAKA PAPER TUBES holds immense pleasure in introducing ourselves as one of

the leading Paper Tubes and Paper Core manufacturers in India.

The Company manufactures all kinds of spiral paper tubes and paper cores for many

different industries and applications. The company also undertakes winding of packaging papers, hygiene papers,

laminated sheets, technical papers,carpets and textile fabrics.

We offer our clients durable and cost-efficient paper tubes and cores.

KPT uses advanced technologies to make best quality products which are

manufactured under strict quality control. The inspection ensures dimensional accuracy,

strength and consistency in quality.

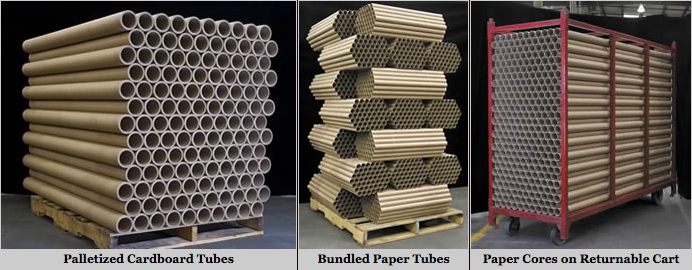

PRODUCT DETAILS

Series of Dia Core

Functional performance of 3mm to 20mm thickness of winding cores are delivered by team K.P.T which has over 15 years of experience in the field. These precision cores with high strength and dimensional stability for the paper and packaging industries are the key components of K.P.T products portfolio.

--- SALIENT FEATURES ---

.jpeg)

PRODUCT FEATURES

K.P.T's core are made from proprietary high-strength core board, produced using our

patented

manufacturing technology. Our core board supports superior horizontal and vertical strength

requirements and ensures outstanding product performance and consistency.

K.P.T's cores offer consistent crushing strength and superior surface finish to minimize

surface markings. Using controlled drying process and maintaining core straightness,

our cores reduces vibrations. The smooth finish provides wrinkle-free winding of material.

As winding speed increases, our cores absorb radial pressure and protect internal diameter

integrity. Proper bonding of layers and grinding of the core ensure that there is no

de-lamination even at high speeds.

The products are manufactured under strict quality control to ensure dimensional accuracy,

strength and consistency in quality. The lab is setup with the technical team to check

raw material quality for craft paper and craft boards with GSM,Bursting factor and cobb value.

QUALITY CONTROLS

3-Point Inspection Process

Inspection Process insures that customers needs are always met with the highest quality tubes and cores. Cores are inspected in our sorting areas, at our cutting stations and in our packaging department prior to delivery to the customer. All tubes and cores are checked for hardness, straightness, dimension stability, thickness and roundness, and to be sure that they are free of contaminants.

Cores are used by manufacturers and converters of film, paper and textiles, using the latest machinery. You can be assured that our cores will meet your needs for any application.

Paper Tube & Core's efforts have resulted in an average cost savings of 10-15% while simultaneously supporting Eco-Friendly efforts that have become primary features of corporate marketing and positioning initiatives.

--- QUALITY TESTING EQUIPMENTS ---

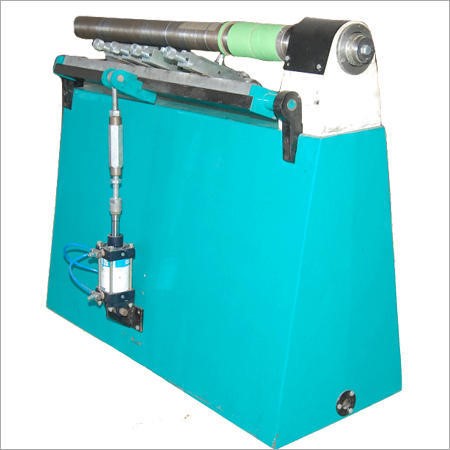

--- MACHINERIES USED ---

CONTACT US

COMPANY 1:

M/S. KARNATAKA PAPER TUBES

#29/3, Behind Wonder Laa, Vajarahalli

Village, B.M. Road, Bidadi Hobli

RAMNAGAR - 562109

COMPANY 2:

M/S. NATIONAL PAPER TUBES

Plot No: 102, Shed No-102,

Graddagunta Village, Akkapetam Post,

Tada Mandal, SPSR Nelloor District

ANDHRA PRADESH - 524121